A new approach to mining site overhaul

Let’s talk minesAddressing common pitfalls in mine operations

Mining sites exist where the orebody dictates, often far beyond any public network footprint or power line reach. Power limitations and connectivity gaps create a patchwork of coverage, leaving crews and equipment cycling through “dark zones” and inconsistent operational visibility.

Every mining project brings together challenging terrain, high-value equipment, extensive support infrastructure, stringent regulations, and environmental risks. Without seamless data flow across these layers, even small disruptions can cascade into delays that erode project margins.

Our global, ground-independent satellite network delivers resilient L-band connectivity that stands up to storms, dust, and fog, and operates on minimal power. Integrating our technology into mine infrastructure strengthens operational continuity and supports strategic business transformation by enabling:

Single connectivity fabric

Actionable IoT data

Always-on team safety

Low cost of ownership

Engineered to take the heat

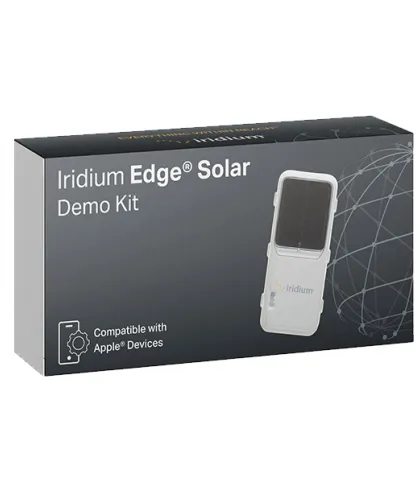

Easy to deploy and easy to manage, our IoT terminals are designed to avoid implementation complexity and accelerate time to value. Purpose-built devices under Iridium Edge® family — Iridium Edge®, Edge® Pro and Edge® Solar — enable satellite connectivity right out of the box, and feature

- Military-grade durability with temperature-, shock-, vibration- and impact-resistant enclosures

- Ultra-low-power profiles for multi-year deployments requiring minimal hands-on maintenance

- Native support for essential sensor inputs to monitor mission-critical environmental conditions

Satellite connectivity, future-proof

Elegant, ultra-slim Iridium modules seamlessly integrate with products of any scale to enable cloud-ready satellite data on existing solutions or streamline new hardware development integrating Iridium connectivity.

Iridium Certus™ 9704

Small message sizes, big business impact

For industrial use cases, Iridium offers two ultra-efficient data services, optimized for power-constrained assets, cloud-native ingress, and total cost transparency.

- Iridium Short Burst Data® (SBD®) — a simple, cost-efficient packet-based service, ideal for applications relying on frequent transmissions of smaller data packets, like sensor reports or heartbeat messages.

- Iridium Messaging Transport (IMT) — a cloud-integrated service that handles payloads up to 100kB; preferred for applications with larger messages, images or file transfers.

An ecosystem of Iridium connected™ solutions

Iridium partners offer a wide range of solutions for heavy equipment telemetry, autonomous fleet management, environmental and earth monitoring.

Iridium Land Mobile Solutions for Remote Mining Operations

Mining sites push equipment, teams, and communications systems to their limit. Our land mobile solutions spanning Iridium Certus® specialty L-band broadband terminals, Push-To-Talk (PTT) services, and rugged satellite phones, give operators the reliable, always-on connectivity needed to keep productivity high and crews safe.

Truly Global PTT for Field Coordination

Rugged Satellite Phones and Access Devices for Safety & Mobility

Specialty Internet Access for Extreme Environments – Iridium Certus

Extract more operational value with Iridium

Leveraging our global network, you can achieve continuous visibility and operational transparency and unlock new levels of productivity above and underground.